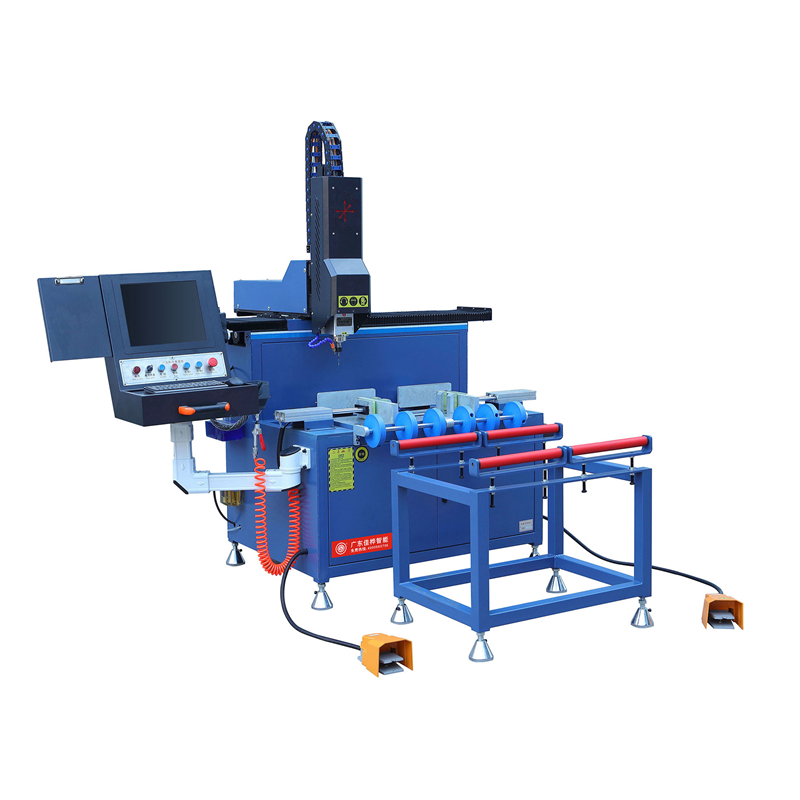

Equipment features

Suitable for processing process holes such as injection holes, movable corner code holes, pin holes, corner protectors, and transmission rod notches in aluminum alloy profiles;

Ø High precision: Using high-precision linear motion pairs, ball screws, gears and racks, it runs smoothly, has high positioning, and has a machining accuracy of 0.05mm.

Ø High efficiency: General/female worker processing, using high-speed variable frequency electric spindle, stable processing, low noise, dual station processing, 6 times more efficient than ordinary processing methods.

Unique chip removal design, equipped with a waste bin, making the site cleaner.

Standard tool life management system; Automatic maintenance prompt function.

technical parameter

Lateral travel (X-axis travel): 800mm

Longitudinal travel (Y-axis travel): 330mm

Vertical travel (Z-axis travel): 300mm

X-axis servo power: 0.75kw

Y-axis servo power: 0.75kw

Z-axis servo power: 0.75KW

Positioning servo power: none

X-axis operating speed: 0~20m/min

Y-axis running speed: 0~20m/min

Z-axis running speed: 0~20m/min

Spindle power: 3.7KW

Spindle speed: 0-12000r/min

Workbench working position: 0 °

Milling cutter specifications: ER25- freely available

Drilling tool specifications:/

Working pressure: 0.6-0.8Map

Brand of tool changing spindle motor: Redworth

Guide rail screw brand: Taiwan Shangyin or Yadeke

Gearbox brand: Newell

System: Dazu System/Scan Code Processing

Flip method: None

Working power supply: 380V/50HZ

Total power of the whole machine: 6.35KW

Lubricating oil setting: automatic lubrication

Processing range (width * height * length): 150 * 150 * 250

Host dimensions: 2300 × 1800 × 2000mm

Weight: 850kg